Home > News > Company News

Release time:2023-12-05

Release time:2023-12-05 Number of views 1704 次

Number of views 1704 次 Hardware molds are specialized tools used in industrial production to produce parts or products of the desired shape from metal materials using various presses and specialized tools installed on the presses. These specialized tools are collectively referred to as hardware molds. When manufacturing hardware molds, the following material properties need to be considered:

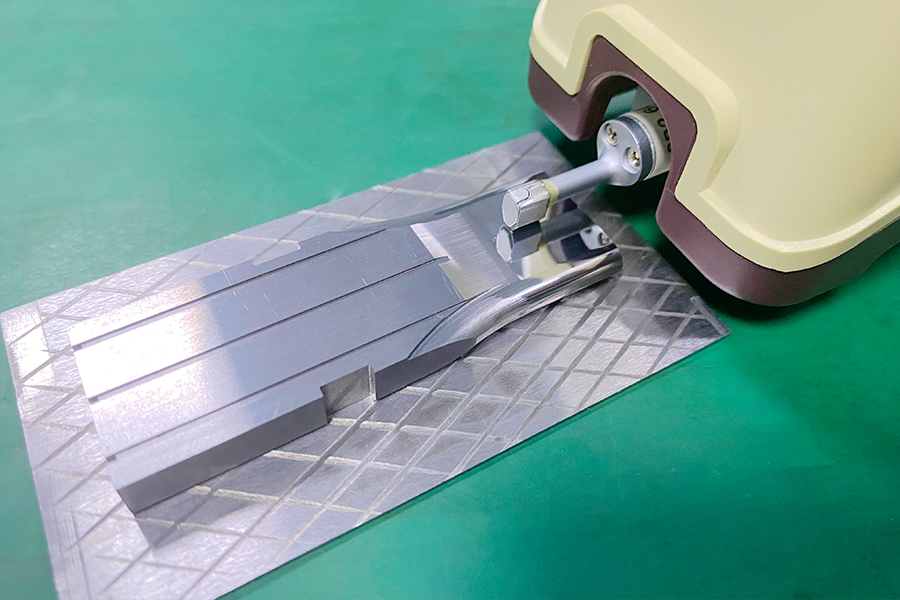

Hardware molds are specialized tools used in industrial production to produce parts or products of the desired shape from metal materials using various presses and specialized tools installed on the presses. These specialized tools are collectively referred to as hardware molds. When manufacturing hardware molds, the following material properties need to be considered:

National Service Hotline:0769-38892066

National Service Hotline:0769-38892066Contact person : Miss Chen

Telephone : 13922521788

Mailbox : fsyw@dgfusheng88.com

Address : No. 14 Zhenxing Road, Jiao Village, Chang'an Town, Dongguan City

Dongguan Fusheng Hardware Mould Co., Ltd. ICP: 粵ICP備19004285號(hào)